Discover in this blog why it’s so inefficient to cut holes in an I-joist, and why cutting into an open web joist involves structural risks. This practice is very disadvantageous, as it can lead to a weakening of the joist’s load-bearing capacity. Let’s see how this can be avoided.

A well-built house relies on the proper integration and interconnection of various systems to ensure functionality, safety, and efficiency. These systems include: electrical, plumbing, heating, ventilation, and air conditioning (HVAC). Each of these systems must be properly installed, maintained, and interconnected to ensure the overall performance and livability of the house.

Installation becomes a key factor in the success of this uniformity, and that’s where TRIFORCE® joists come in. Its open web design eliminates the need to drill holes to accommodate pipes or wires.

Problems and limitations linked to cutting holes in I-joist

Many problems can occur when it comes to cutting holes in I-joist, some of which can have great consequences:

1. Increased risk of failure: if the holes are not made where indicated by the manufacturer or engineer, it can weaken the joist and increase the risk of failure.

2. Bouncy floor: Drilling holes may result in a bouncy floor due to the fact that deflection has been increased, this can compromise comfort and even safety.

3. Lower load-bearing capacity: Holes can reduce the joist’s load-bearing capacity as well, potentially leading to structural failure.

4. Splintering and cracking: Improper cutting techniques or using dull tools can increase possibility the of splintering and cracking.

Not to mention that you can face a lot of limitations:

1. Minimum distances must be observed from the ends, top, and bottom of the joists.

2. Minimum distances between holes must be adhered to.

3. Maximum sizes of holes must be respected.

4. Exercise caution to avoid overcutting the corners of square holes.

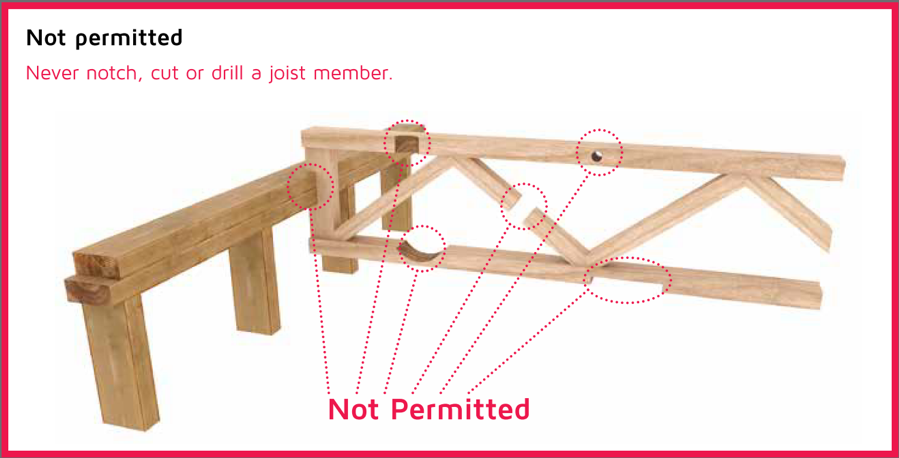

5. Do not cut or notch the flanges. These upper and lower members are engineered to endure significant compression and tension, making them compromised when cut.

Cutting holes in an I-joist may expose the contractor to considerable risk. In addition, cutting holes wastes time and money. These are two key factors in the construction business. Effective management of these resources is essential to the successful completion of a construction project. Staying on time and on budget can be critical to a project’s success. What’s more, delays or cost overruns can have a significant impact on profitability and customer satisfaction.

So, using TRIFORCE® as your open joist system is part of careful planning and rigorous management to balance these two crucial factors. The time savings can be explained as follows: cutting or drilling holes is time-consuming and even more so, if there’s an improper hole placement, if they are too large, too close to the top or bottom flanges, or too close to other openings. You may have to wait for a joist replacement or a repair detail from an engineer.

What to do when you have to cut/notch an open web joist :

1. Avoid notching in the upper chord or lower chord

All engineered wood floor joist manufacturers agree: floor joist notching must be avoided at all costs as it can weaken the structural integrity of the joist. More precisely, there is the possibility of joist breakage, and in particular notching in the upper chord or lower chord, can lead to joist failure.

In fact, floor joists are designed to support the weight of the floor and any loads placed on it. When you notch a joist, you remove a portion of its structure, reducing its ability to carry the load effectively.

2. Consult a professional

If notching is absolutely necessary, it is essential to consult a structural engineer or qualified professional to ensure that the notching is carried out correctly and does not compromise the structural integrity of the floor system. If notching is incorrectly positioned, it can compromise the strength and rigidity of the joist. In fact, it can lead to uneven floors, squeaking and other structural problems.

3. Adjust the joist placement or choose TRIFORCE® open-joists

Joists are often positioned directly beneath a bathtub or toilet as per the initial design. While the exact placement of these fixtures may change during construction, knowing the precise locations allows the general contractor to adjust the joist placement slightly, ensuring that its top chord remains intact and doesn’t need to be cut.

In the case of most TRIFORCE® open-joist floor structures, the joist can be shifted by 3 to 4 inches. This flexibility hinges on effective communication among the builder, designer, and either the plumber or electrician involved in the project.

If you accidentally drill, cut or notch a joist, we can provide you with repair details. You can find these free-of-charge on our web site in the common repairs section. They are simple and do not require removal or replacement of the entire joist.

Why not learn more about this product, much appreciated by many, by downloading our spec guide:

Great article. the placement of sink and toilet drains is an important matter often leading to field changes. The advantage of open web joists for accommodating HVAC, plumbing and electrical infrastructure cannot be overstated. And lastly, finger jointed and glued open web joists without steel plates look much better (and is safer) in an open basement.

Thank you very much for your pertinent comment, we appreciate sharing ideas.