Guarantee the durability of your construction project with proper installation of TRIFORCE® open web joists and all other important floor components.

Ensuring the correct installation of TRIFORCE® open web joists is critical to achieving a durable and efficient floor system. This blog will cover the key components of an open web floor structure and how to properly install TRIFORCE® joists, strongbacks, and rim board to enhance structural performance.

1. Installing TRIFORCE® Joists for a Sturdy Open Web Floor System:

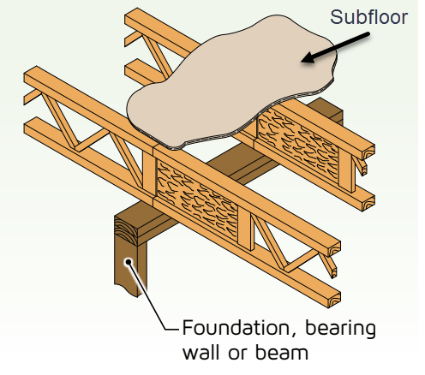

Joists are the main component of the floor system, but it is important to respect the recommended spacing and maximum loads to ensure that their functions are at their full potential. They transmit loads to the load-bearing wall, foundation or beam. In addition, the role of joists is to transfer loads more evenly over the floor surface.

TRIFORCE® Joist Installation Tips for Optimal Performance:

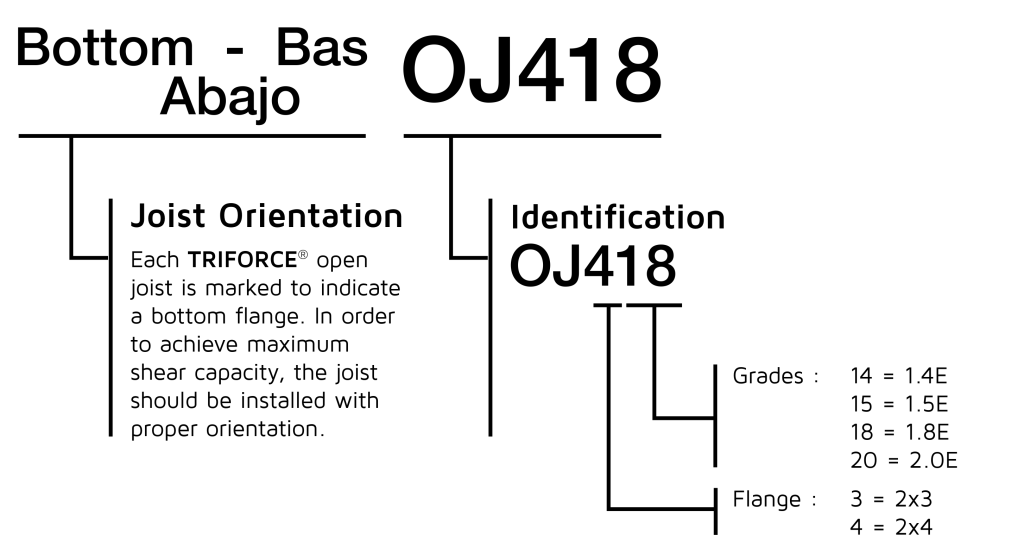

- Joist Marking for Clear Installation Guidance: An important point about TRIFORCE® joists that helps installation is the identification on the underside of the joist. It provides clear and easy-to-read markings, which can significantly streamline the installation process and provide maximum shear capacity. These markings typically indicate important information for builders and contractors so that they can verify that the correct joists are being used in the proper locations, reducing the risk of errors.

- Ensuring Correct Bearing Surface Support: Each end of TRIFORCE® joist must rest on a support at least 1 1/2″ wide to ensure correct load distribution and structural stability. Actual bearing will be determined by the software layout.

- Trimmable Section Adjustments for Joist Length: It is possible to adjust the required length of a joist by cutting the end of the OSB panel by up to 24″. However, it is not permitted to cut the side with the 2×3 post.

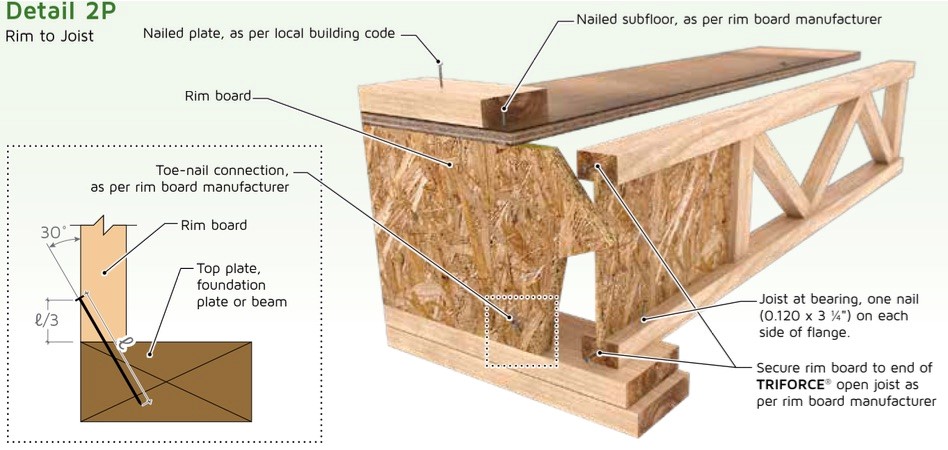

- Avoid tipping over: At the ends, the joists must be restrained to prevent overturning. Use a rim board or blocking panels.

- Guidelines for Proper Load Suspension on Joists: Apply concentrated loads only on the top flange. Do not suspend concentrated loads from the bottom flange unless they are light loads, such as ceiling fans or light fixtures.

- Use TRIFORCE® Joists in Dry Environments Only: TRIFORCE® open joists must be used only in interior applications.

- Rot prevention: As with all wood products, these joists must not be in direct contact with masonry or concrete.

2. The Importance of Strongbacks in TRIFORCE® Open Web Floor Systems :

Strongbacks play a key role in structural durability and stability. When continuous links are correctly installed, there is a significant reduction in vibration which improves the comfort and performance of the engineered floor system. When installed correctly, strongbacks are a simple addition that significantly increases the performance of the floor system.

Placed on edge on the joist’s bottom chord, strongbacks run continuously through the floor framing cavity. Ensure that at least 3 joists are connected per strongback.

3. Subfloor Installation: Enhancing Floor Rigidity and Soundproofing:

Guaranteeing a solid base for the cladding, subfloor adds rigidity and helps distribute loads. It can also help reduce sound transmission and provide thermal insulation. In summary, the subfloor enhances the comfort for inhabitants. Plywood or OSB are common materials used for subfloors, particularly in residential construction. Please follow proper subfloor installation instructions.

4. Floor Joist Rim Board: Ensuring Stability in Your TRIFORCE® Joist Setup:

Installed perpendicular to the joist direction, the rim board is mandatory on exterior and interior walls that are perpendicular (or at an angle) to the joist direction. Its primary function is to transfer both vertical and lateral loads. Connecting the rim board to the joists ensures stability by providing sideways support and preventing the joists from twisting or turning. During storms or high winds, the rim board helps reinforce the floor by providing a solid connection that reduces movement and enhances overall stability.

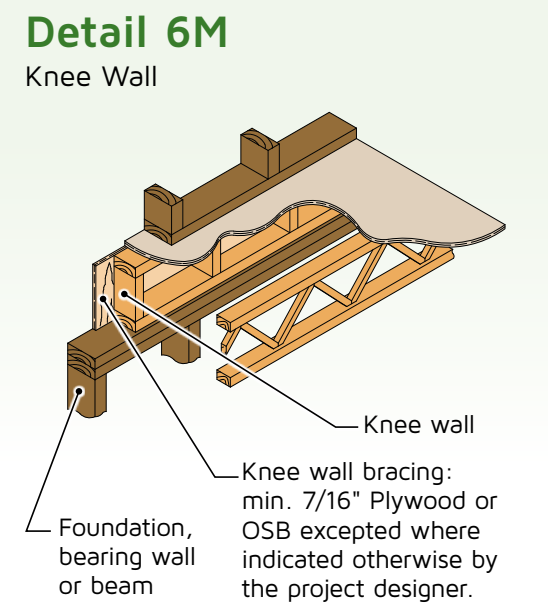

How to Use Knee Walls in a TRIFORCE® Open Web Joist Floor System:

It serves as a starting point for the floor and runs parallel to the joists. It can be either 2×4, 2×6 or 2×8. Knee walls should always be braced laterally with a structural panel. The structural panel should be nailed to either side of the wall.

A useful construction technique would be, where the knee wall and the rim board intersect, to always ensure that the rim board completely covers the end of the knee wall. That will ensure a solid connection.

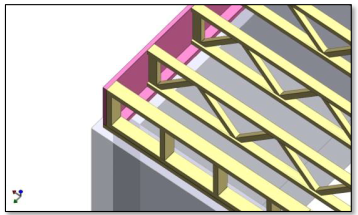

View from below :

View from above :

The maximum efficiency of a floor is achieved through careful design and rigorous construction, where each element interacts harmoniously with the others. Joists, knee walls, load-bearing beams, rim joist, subfloor and strongbacks must all work together to create a stable, durable structure capable of supporting the anticipated loads.

In conclusion, proper installation of TRIFORCE® open web joists is essential for achieving a durable and efficient floor system.

By following best practices for joist spacing, utilizing strongbacks for added stability, and ensuring the correct application of rim boards and subfloors, builders can significantly enhance the structural integrity of their projects.

The careful attention to detail in each component not only improves load distribution and reduces vibration but also contributes to the overall comfort of the occupants.

Discover the Power of TRIFORCE® Open Web Joists: Maximize floor system performance with superior strength, flexibility, and ease of installation.

Ready to take your project to the next level?

Download our detailed spec guide now and get all the technical specs you need for flawless installation.