As we explained in our previous article, the Open Joist TRIFORCE® is made with four components. We saw how two of them (the chords and the OSB panel) are prepared for assembly. Today, it’s time to examine the posts and webs!

The posts and the webs

There are two posts in the Open Joist TRIFORCE: one pre-assembled with the OSB panel and one at the other end, “closing” the joist.

Once again, inspection is the key here, and the quality of all the lumber is thoroughly verified. The lumber is then cut to length before being sent on a conveyor that sorts the posts and webs into their respective bins.

Both components are then milled to have five groves on each end and sent to the final assembly line.

The final assembly

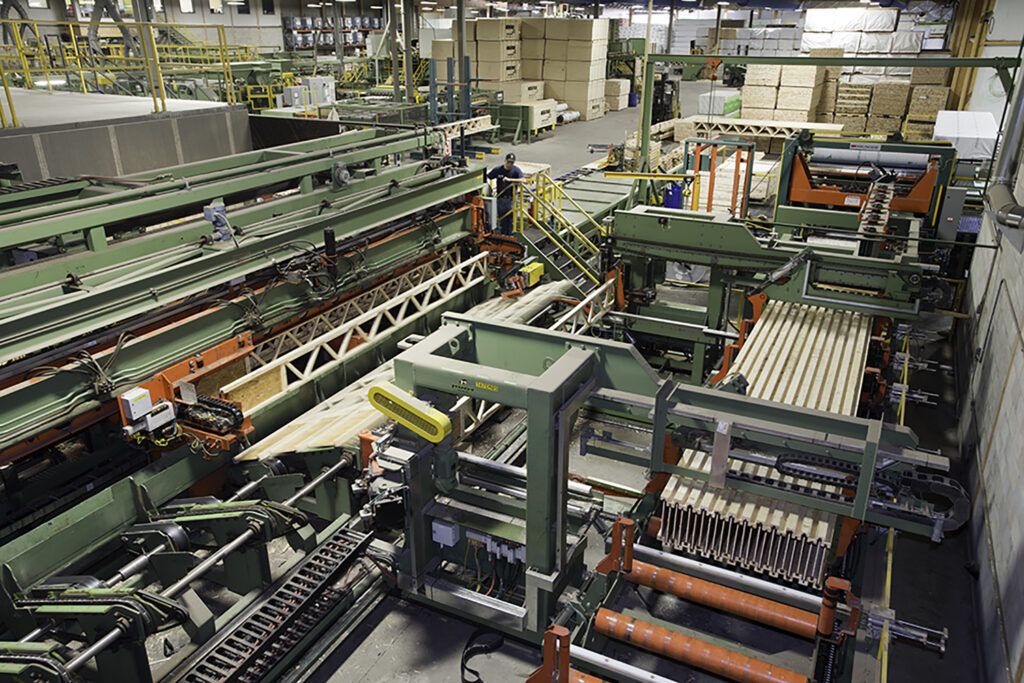

The final assembly consists of attaching the webs and the last post to the prepared sub-assembly (chords, first post and OSB panel).

Robotics is used to apply adhesive to the ends of the webs and set the webs between the chords. The same process is followed for the last post.

What next? The joist is sent to a press which assures that the joist is the right height and makes sure the components are perfectly positioned. Once pressed and set, we stack the joists and send them to a curing room for about two hours, which is the time necessary for the compound adhesive to complete its reaction and realize its strength.

After one last visual inspection, we test every single Open Joist TRIFORCE. We always test them individually. Those that make the cut are sent to be packaged and wrapped. Those that failed are destroyed (not many though, about 1 out of 1,000).

The process is all automated, and every joist is carefully inspected and tested by independant third-parties to make sure it provides the best performance for all of our customers!