Have you ever heard of a cantilevered extension? If you work in the construction industry, you probably have an idea of what it refers to.

Cantilevers are commonly used to extend the length of a floor system beyond the supporting wall or beam. It can be a simple balcony, or an entire room suspended on one side of the façade.

This technique is very often used in modern architecture, as it adds a unique design feature that stands out. You can easily execute cantilevers with TRIFORCE® open web joists.

In contemporary residential architecture, these extensions are very popular. It can add space to a home that is too cramped, especially for those with a small property footprint.

In a typical joist cantilever, the joists are extended beyond the supporting beam or wall, with the extended portion of the joist known as the cantilever. The cantilevered portion of the joist is supported by the remaining portion of the joist that is still attached to the supporting beam or wall.

In general terms, joist cantilevers are commonly used in residential construction to create overhangs for porches, balconies, and other architectural features. They can also be used to extend the length of a room or to create additional space for storage or other purposes.

It is important that the joist cantilever is designed and constructed properly to ensure its stability and safety, so that your engineered wood floor joist system will be at its greatest performance.

The length of the cantilever, the size and spacing of the joists, and the type of wood used are all factors that must be considered in the design process. Additionally, local building codes and regulations must be followed to ensure compliance with safety standards. Verification of loading using manufacturer’s Analyzer software will determine what type of reinforcement may be required for your floor structure.

Here are some essential rules to know when it comes to designing and calculating a cantilever with TRIFORCE® open joist:

The 1/3 rule: joists or dimensional lumber- cantilevered should normally comply with the following rule: the inside length of the overhang must be at least twice as long as the overhang in question.

So, if we have 2’-0″ cantilever, it will be necessary to step back from 4’-0″ inside the building.

When it comes to cantilever floor joist framing, there are 2 scenarios that can occur:

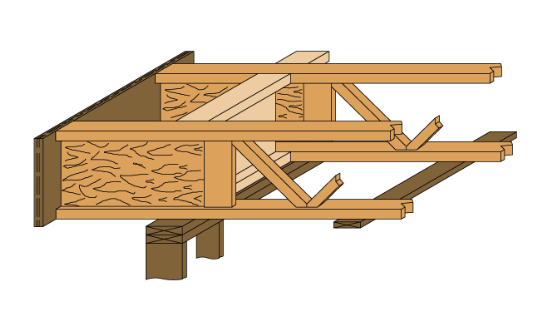

1) Parallel to joist direction as shown in the illustration above where the TRIFORCE® open joists themselves are cantilevered.

Or, as shown in the illustration below where solid lumber (2X’s) are attached to the TRIFORCE® to create the cantilever.

In this scenario, while the open web joists stop at the exterior bearing, 2X members are fastened to the sides of the TRIFORCE® joists so that they are tight against the joist webs and under the top chord of the joist. 1-1/2” dimension lumber is attached to the top of this 2X so that the cantilever can achieve the same top plane as the open joist. Where this 2X crosses the bearing, a solid wood filler is needed to transfer load. If the cantilever is being extended from the trimmable I-Joist end of a TRIFORCE® joist, a 5/8” wood filler is required on the OSB panel.

2) Perpendicular to joist direction as shown in the illustration below:

With TRIFORCE® open joists, it is possible to construct a cantilever perpendicular to the joists by installing solid lumber (2X’s) through the open webs of the joists to create the cantilever

The recommended maximum extension for a cantilever perpendicular to the joists is four feet. In this scenario, the 2X’s should extend back into the floor at least eight feet, using a recommended 2:3 ratio. It is possible to extend beyond four feet but each situation must be examined and analyzed for structural capacity.

In all cases where dimension lumber is used for framing an exterior deck, it is recommended that treated lumber be used.

For more information about framing cantilevers in a TRIFORCE® floor system, please download our spec guide. Contact us with any questions. We’ll be glad to help.