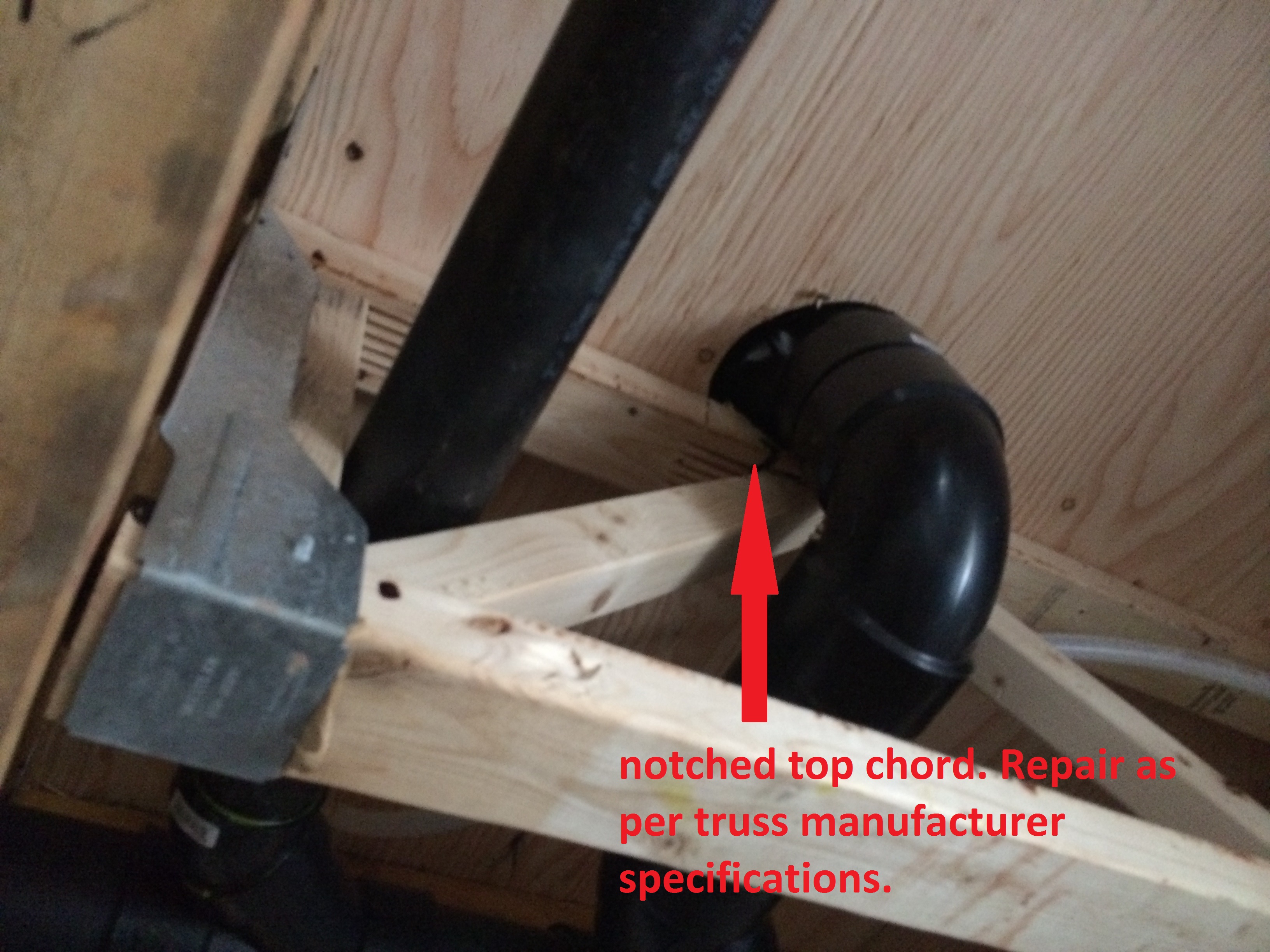

Manufacturers of engineered wood floor joists are unanimous on this point. Never, ever notch a floor joist or bore through the chords. Upper chord or lower chord, notching is prohibited because it could cause the joist to fail. Yet joist frequently get mistreated this way. Why? How can we avoid notching floor joists altogether?

Planning to avoid notching

In the design stage, it makes sense to work with uniform joist spacing because it makes load calculations easier. This can be the traditional 16″ o.c. but with engineered wood joists, 19.2″ o.c. and 24″ o.c. are also popular joist spacing specifications.

Toilet and bathtub drainpipes are the usual cause of joist notching. Consequently, if both drop down right in the middle of two joists, there should be no problem. But designers plan foundation, framing and loadbearing before they get to bathroom fixture placement. The placement of the joists doesn’t always end up being ideal.

It’s the completed bathroom walls that will determine exact placement of the toilet and tub drains. Building code specifies minimum distances between bathroom fixtures and walls, as well as between fixtures. A bathroom can come in many layouts. If the exact placement of the fixtures isn’t planned in relation to the completed walls and the joists, that’s when you end up notching floor joists.

That’s why this detail has to be settled at the design stage. The positions of the toilet flange and bath drain in relation to the completed walls must be established in the plan.

Discrepancies between planning and execution

So It takes careful planning to ensure both toilet and bathtub drainpipes end up clearing the joists. But once construction has started, it is possible that something won’t measure up according to plan. What if the foundation is slightly off? What if the walls aren’t exactly where they should be?

One other way to avoid notching floor joists is to build some leeway into the plan through the positioning of the joists. It is important to note here that joist spacing isn’t specified by building codes. That’s because spacing is less important than span, load bearing capability and floor deflection criteria. A designer can move a joist off center below the bathroom to allow for discrepancies in planned placement of the drain, so long as load and deflection are properly accounted for. Likewise, a builder can recommend and execute such a change, so long as it is vetted by the designer or a structural engineer.

Ideally, the handling of these changes should be done in consultation with the plumber before work begins. Communication between designer, builder and plumber will help avoid having to repair damaged joists.

If you’d like information about TRIFORCE<sup>®</sup> open joist, download our Specifications guide. The open joist TRIFORCE<sup>®</sup> is designed to make plumbing, electrical and HVAC installation easier with it’s open design.

If you already using Triforce and require a repair detail, by all means contact us!

This is often the case where the floor and house designer don’t work together.

Great article.

Hi Steve,

Thanks very much. I had this conversation with a builder last week. He was adamant about pre-designing the plumbing penetrations before the building of the project.

I let him know we are now in our design methodology adding the toilet drains, shower drains and the tub cutouts to

remove any slowdowns and damage to the joists. Working like this eliminates a lot of hassle for the plumber and builder if the

plumbing penetrations are accounted for up front in the design. This will reduce time and ultimately cost.

It’s one of the ways people should be working together, if they aren’t already.

Eric.