It’s not enough to simply specify the right components for a building project. An architect, engineer or designer must also specify how those components should be installed… how the pieces connect to one another. Sometimes a simple fastener schedule is adequate when wood-to-wood connections are needed. But often, especially in today’s world of engineered building components and innovative framing practices, engineered connectors are required to ensure the structural integrity of a building.

We see engineered steel connectors specified for roof truss installation and for bracing in seismic activity areas. But most often, we see the use of steel connectors when floor systems are being framed. In floor framing, wood-to-wood and wood-to-steel connections are the norm. How floor joists are connected to plates, beams and other bearing requires specific knowledge of loading conditions and information about the steel connectors available today.

Getting The Hang Of It

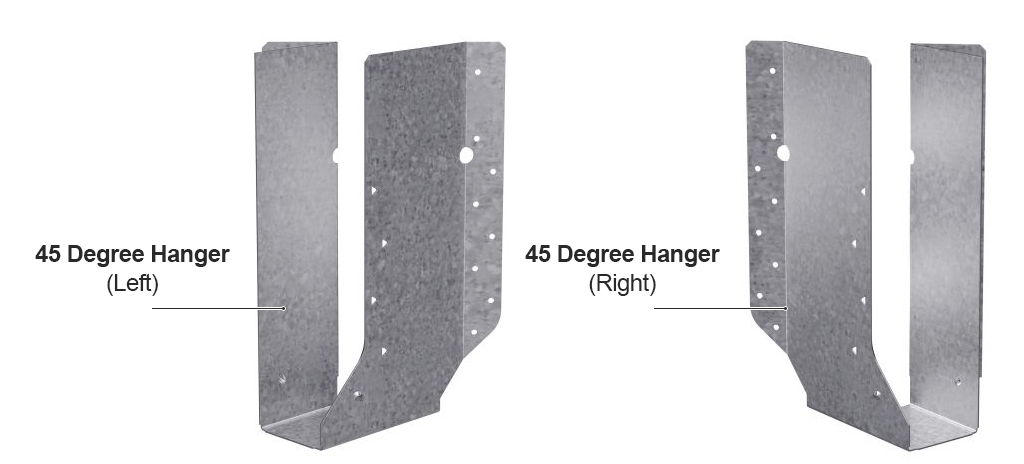

Joist hangers do exactly what their name says. There are several types: Top Flange, Face Mount, Single Joist, Double Joist, Skewed and Height Adjustable. Steel connector manufacturers offer products for all conditions and provide in-depth product information guides as resources for design professionals.

Manufacturers’ Hanger Load Tables contain information necessary to choose the correct hanger for the situation and install it properly. Arranged by joist size, these tables show the dimensions of hangers, the quantity and type of fasteners required for their installation and their allowable loads to be considered when designing a floor system. In addition to sizing a hanger adequately for its load, the table is the authority on the number of fasteners to be used in the header and the hanger…specifications that should not be ignored.

Hangers can be used to meet special framing challenges. Top flange hangers allow a bottom-chord-bearing joist to install like a top-chord-bearing truss. Face mount hangers can be used to install joists in some special balloon-framed structures.

Getting It Together

Hangers can connect TRIFORCE® floor joists to steel I-Beams, either by fastening them to wood filler plates attached to the steel or welding hanger top flanges to the beam. Attachment to wood beams can be accomplished with top flange hangers or face mount type.

Special steel connectors are sometimes used when framing a floor system with the open joist TRIFORCE®. In cases where joists must be doubled in order to carry a heavy load, special fasteners are available to connect the two joists together so that they act as a single girder joist. In such a situation, the aforementioned double joist hanger may be required.

Manufacturers of steel connectors offer a full array of products that can be used to connect and install TRIFORCE® floor joists. See below for examples of some common connection situations.

Dear Larry

I am interested in learning what is the approximate hanger cost (material and labour cost) of a single joist?

Tuomo