Building with engineered wood floor systems allows for wider spans, greater strength, and far more design possibilities than traditional solid sawn lumber. But to capture all the benefits of TRIFORCE® joists, here are some recommendations for floor system installation:

A) Use the manufacturer’s recommended hangers and fasteners

Joist applications can vary, and there are hangers and fasteners for many different load conditions. It’s definitely not one size fits all. Given that most structural failures happen at connection points, it’s better to play it safe. Use the manufacturer’s recommended connectors.

B) Verify your design using the manufacturer’s literature/software

Parameters such as spans, load conditions, joist spacing and deflection are interrelated. Building codes don’t dictate open joist span tables or joist spacing, however, they do specify load conditions and deflection. Verify your design by checking all four of these factors with the manufacturer’s literature (TRIFORCE®span table) or Analyzer® software.

The manufacturer can help you validate that the combination of products used in the design meets minimum requirements, and also help you create a better design.

C) Consider reducing deflection beyond code requirements

Deflection is the up and down movement of a floor system under load. Reducing that movement can increase perceived quality of the floor system. There are a few ways to do this: you can reduce on-center joist spacing. You can also increase the joist depth or use joists with a larger flange or chord (denoted with a S in the Available Joist Sizes table which can be found in the Specifier Guide). Decreasing deflection below code recommendations can increase comfort and reduce the possibility of occupant complaints.

D) Use joists that enable easy mep installation

Joists with an open web design such as TRIFORCE® allow for much quicker plumbing, electrical and HVAC installation. Tradesmen have more freedom in choosing their piping or wiring runs. TRIFORCE® also eliminates the need to drill holes through individual joists and thus reduce possible weakening or damage.

6 performance factors tips for floor system

Open-web floor joists like TRIFORCE® do a better job than solid joists of dispersing floor system vibrations, lessening vibration’s effect on people because

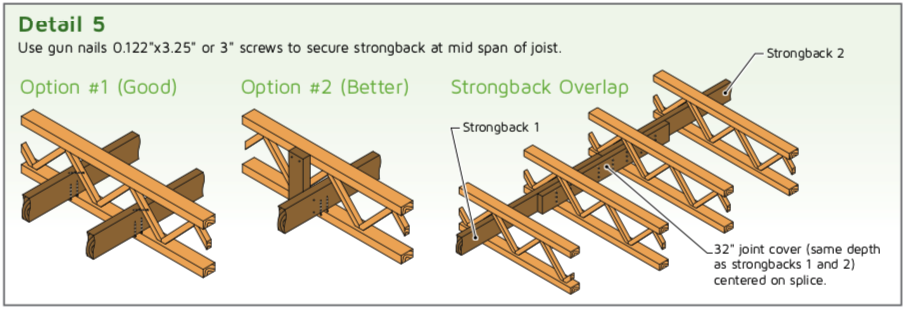

they allow for the installation of continuous ‘’strongback’’ bracing. Strongbacks effectively minimize vibration by helping the floor work as one entity.

- Strongbacks can be continuous and even overlap. Combined with TRIFORCE®, they help improve floor performance.

They must be of dry lumber and installed as close as possible to mid-span and can be cut between two joists for ducts or pipes, if needed. - Deeper joists will reduce deflection and vibration.

- Reduced on-center joist spacing will improve floor performance.

- Thicker floor decking installed with adhesive and fasteners provide a better “feel”. Screws are more effective fasteners than nails.

- Framed partition walls help dampen vibration. Wall plates should be fastened through floor decking into floor joists.

- When possible, use of a bearing wall to support the ends of joists rather than a suspended beam will result in a stiffer floor system with less vibration.

3 other tips for a floor system installation at its best

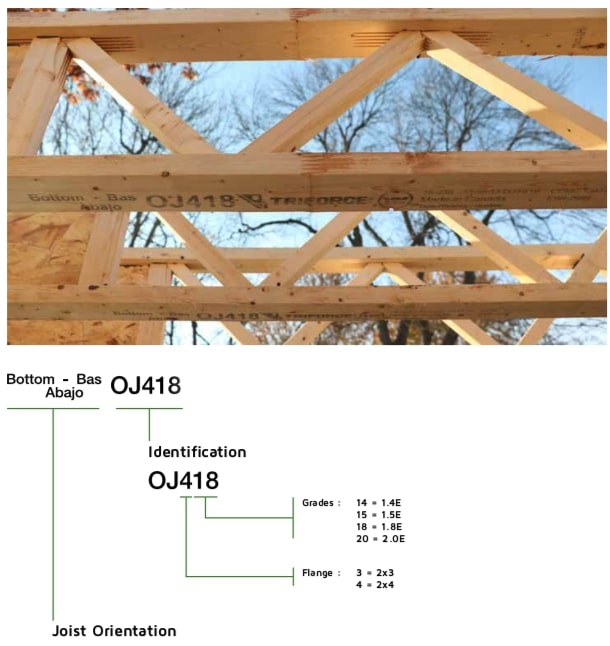

- Pay attention to the marking. Each TRIFORCE® joist has a top and a bottom. Proper orientation is marked on the joist and framers should abide by these markings to ensure correct installation and to achieve maximum shear capacity. And, it’s a good idea to confirm correct orientation before decking is installed and mechanical systems have been run. But, even if installation errors are discovered, in most cases, upside-down installation presents no problems related to joist performance and, if needed, “fixes” are available.

- Take a good look at the plans. Before joist installation begins, a few minutes of comparing joist placement plans and mechanical systems installation layouts can help avoid future delays and headaches. At this stage, there is an opportunity to discover possible conflicts with access openings for mechanical systems (such as plumbing drops) and TRIFORCE® joist locations. It’s a good idea to make a point of warning to MEP installers not to alter TRIFORCE®joists.

- Make sure to have proper joist direction. TRIFORCE® open joists feature a trimmable end with an I-Joist configuration and an opposite end with a 2X3 vertical block. It is recommended that the end with the 2X3 be installed on the straightest wall or beam run. This will ensure that the joists…and open spaces…line up from joist to joist. Then, mechanical systems can be installed in the least amount of time, allowing these systems to operate with optimum efficiency.

Glad to help

Barrette Structural Distribution is happy to offer these tips to help ease installation of TRIFORCE® floor joists so that end users may enjoy the full benefits of TRIFORCE® floor systems. Refer to the Installation Guide for additional information. Our guidance is designed to help you provide peace of mind underfoot!

If you’d like to find out more about TRIFORCE® floor systems download our spec. guide :